Author: Admin Date: 2024-04-19

How to lubricate and maintain the Gear DC geared motor with cover?

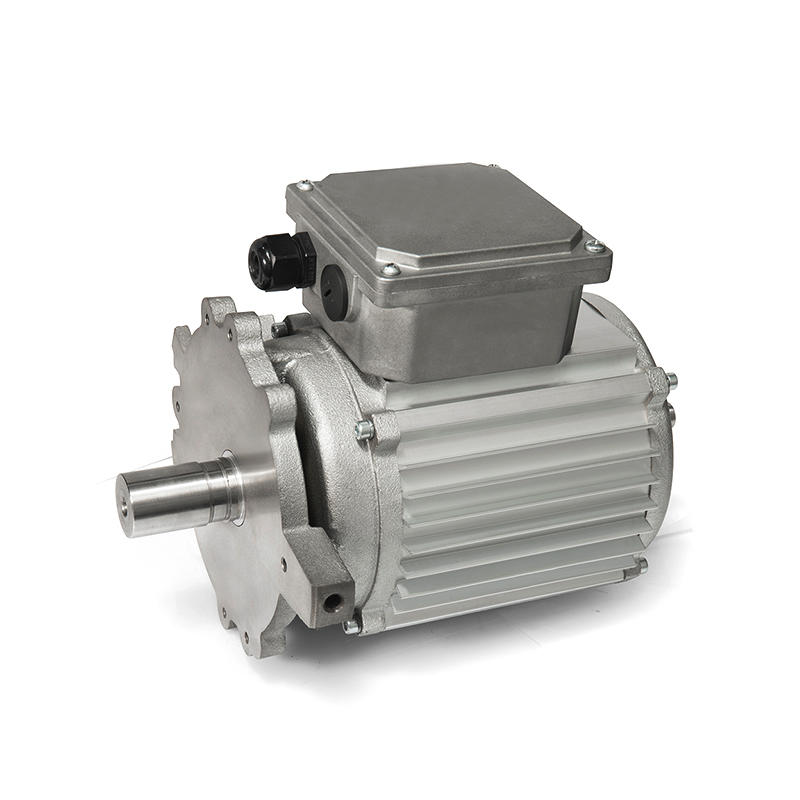

In industrial production, the Gear DC geared motor with cover is a commonly used power equipment, and its normal operation and service life are inseparable from lubrication and maintenance. Correct lubrication and maintenance measures can not only extend the service life of the motor, but also maintain its efficient and stable working condition. This article will introduce the lubrication and maintenance methods of Gear DC geared motor with cover to help users better maintain the motors.

Before performing lubrication maintenance, you first need to select a suitable lubricant. Common lubricants include lubricating oil and grease. Select the appropriate lubricant according to the use environment and working requirements of the motor. In general, lubricating oil is recommended for high-speed operation and high-temperature environments; while under heavy loads and harsh environments, grease may be more suitable.

The gear transmission system of the Gear DC geared motor with cover is a key operating component and requires regular lubrication and maintenance. According to the frequency of use and working conditions of the motor, formulate the corresponding lubrication cycle. It is generally recommended to perform lubrication maintenance every three months to ensure the smooth operation of the motor.

When lubricating, the motor should be stopped first, the cover on the motor should be removed, and the dirt and debris on the gears and bearings should be removed. Then, apply an appropriate amount of lubricant evenly on the gear and bearing surfaces, and turn the motor handwheel so that the lubricant fully lubricates each moving part. Finally, install the cover and restore normal operation of the motor.

When performing lubrication maintenance, attention should be paid to controlling the amount of lubricant added to avoid excess or deficiency. Excessive lubricant will increase friction resistance, reduce transmission efficiency, and even cause overheating and oil leakage; while insufficient lubricant will cause increased wear of gears and bearings, affecting the normal operation of the motor.

Regularly check the lubrication condition of the Gear DC geared motor with cover, and deal with any abnormalities in a timely manner. If the lubricant is found to be dirty or solidified, it should be cleaned immediately and replaced with new lubricant; if the lubricant is found to be missing or insufficient, it should be replenished in time. Regular inspections can also detect other faults and problems with the motor, and repair and replace them in a timely manner to ensure long-term and stable operation of the motor.

Through correct lubrication and maintenance measures, the service life of the Gear DC geared motor with cover can be effectively extended and its efficient and stable working condition can be maintained. Therefore, users must pay attention to lubrication and maintenance work when using motors, and do a good job in motor maintenance to ensure the normal operation of the equipment and the improvement of production efficiency.

Before performing lubrication maintenance, you first need to select a suitable lubricant. Common lubricants include lubricating oil and grease. Select the appropriate lubricant according to the use environment and working requirements of the motor. In general, lubricating oil is recommended for high-speed operation and high-temperature environments; while under heavy loads and harsh environments, grease may be more suitable.

The gear transmission system of the Gear DC geared motor with cover is a key operating component and requires regular lubrication and maintenance. According to the frequency of use and working conditions of the motor, formulate the corresponding lubrication cycle. It is generally recommended to perform lubrication maintenance every three months to ensure the smooth operation of the motor.

When lubricating, the motor should be stopped first, the cover on the motor should be removed, and the dirt and debris on the gears and bearings should be removed. Then, apply an appropriate amount of lubricant evenly on the gear and bearing surfaces, and turn the motor handwheel so that the lubricant fully lubricates each moving part. Finally, install the cover and restore normal operation of the motor.

When performing lubrication maintenance, attention should be paid to controlling the amount of lubricant added to avoid excess or deficiency. Excessive lubricant will increase friction resistance, reduce transmission efficiency, and even cause overheating and oil leakage; while insufficient lubricant will cause increased wear of gears and bearings, affecting the normal operation of the motor.

Regularly check the lubrication condition of the Gear DC geared motor with cover, and deal with any abnormalities in a timely manner. If the lubricant is found to be dirty or solidified, it should be cleaned immediately and replaced with new lubricant; if the lubricant is found to be missing or insufficient, it should be replenished in time. Regular inspections can also detect other faults and problems with the motor, and repair and replace them in a timely manner to ensure long-term and stable operation of the motor.

Through correct lubrication and maintenance measures, the service life of the Gear DC geared motor with cover can be effectively extended and its efficient and stable working condition can be maintained. Therefore, users must pay attention to lubrication and maintenance work when using motors, and do a good job in motor maintenance to ensure the normal operation of the equipment and the improvement of production efficiency.

-

Feedback

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体